What a 7-Way Trailer Plug Does

The 7-Way RV Blade connector is the industry standard for equipment trailers, dump trailers, enclosed cargo trailers, campers, goosenecks, and most trailers equipped with electric brakes.

This connector provides circuits for lighting, electric brakes, 12-volt auxiliary power, and typically a reverse/backup circuit.

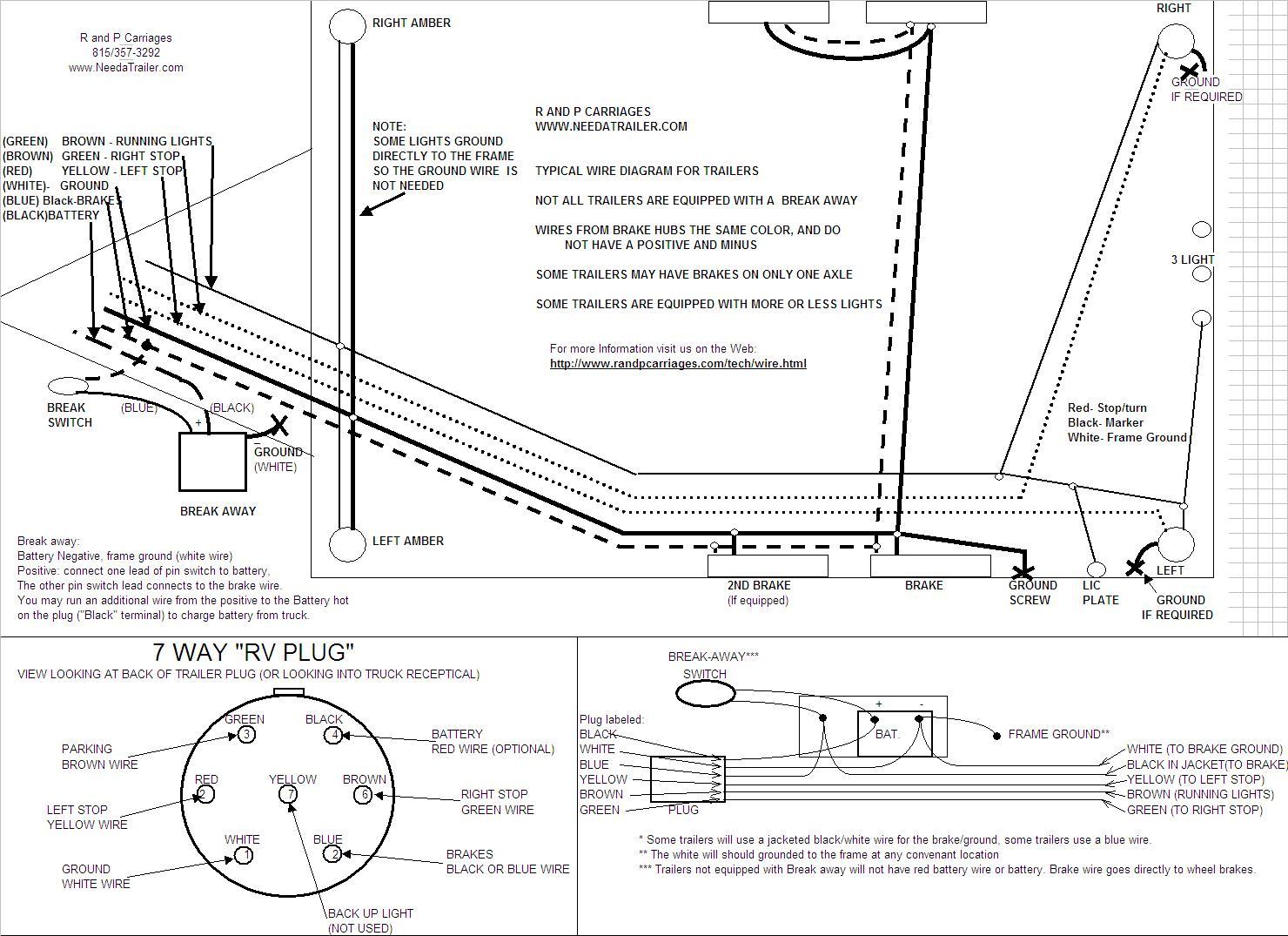

7-Way Plug Style Reference

Below are the standard trailer-side and truck-side 7-way blade connectors.

Standard 7-Way Wiring Code

| Connector Wire | Function | Typical Trailer Wire |

|---|---|---|

| White | Ground | White |

| Blue | Electric Brakes | Blue |

| Green | Tail / Running Lights | Brown |

| Black | 12 Volt (Hot Lead) | Black |

| Red | Left Turn / Brake | Yellow |

| Brown | Right Turn / Brake | Green |

| Yellow (Center Pin) | Auxiliary / Backup | - |

Pin Number & Recommended Wire Gauge

| Pin # | Color | Gauge | Circuit Function |

|---|---|---|---|

| 1 | White | 10 Ga | Common Ground |

| 2 | Blue | 12 Ga | Electric Brakes |

| 3 | Green | 14 Ga | Tail / Running Lights |

| 4 | Black | 10 Ga | Battery Charge (+) |

| 5 | Red | 14 Ga | Left Turn / Stop |

| 6 | Brown | 14 Ga | Right Turn / Stop |

| 7 | Yellow | 14 Ga | Auxiliary / Backup |

7-Way Wiring Diagram

The diagram below illustrates proper wiring orientation and terminal positions.

Interior Connector Orientation

Wire Size Guidelines

- 16 Gauge – 10 amps – Lights only

- 14 Gauge – 15 amps – Lights + up to 2 brake axles

- 12 Gauge – 20 amps – 3 brake axles, 12V AUX feed, typical ground

- 10 Gauge – 30 amps – Heavy loads, campers, high-draw applications

If you operate multiple brake axles, interior lights, hydraulic pumps, or charge batteries, calculate your total load and size wiring accordingly.

Grounding – The Most Common Failure Point

- Never rely on the hitch ball for ground.

- Ground must be securely attached to the trailer frame.

- Ground should be attached at more than one location when possible.

- Ground wire must be properly sized to handle full system load.

Important Lighting Note

Trailers do not have independent brake lights.

They use:

- Left Turn / Stop

- Right Turn / Stop

If turn signals function but brake lights do not, the issue is typically on the truck side.

Common 7-Way Plug Problems

- Corrosion inside connector

- Loose or spread terminals

- Broken ground wire

- Undersized brake wire

- Damaged junction box connections

Trailer Plug Maintenance

- Apply regular grease to connector pins.

- The green corrosion seen on plugs is copper oxide.

- Keep terminals coated to prevent oxidation.

- Inspect pins regularly for looseness or cracking.

- Replace damaged housings immediately.

Proper wiring, grounding, and wire sizing are essential for safe trailer operation. When in doubt, verify pin orientation and confirm circuit function before replacing components.

0 comments