What Electric Trailer Brakes Do

Electric trailer brakes convert electrical signal from your tow vehicle into mechanical braking force at each wheel. When you press the brake pedal, your brake controller sends power through the blue brake wire to the trailer’s brake magnets. The magnets activate the brake shoes inside the drum, slowing the trailer.

This system allows proportional, adjustable braking that works in sync with your tow vehicle.

Main Components of an Electric Brake System

- Brake Controller (inside truck)

- 7-Way Trailer Plug

- Brake Wire (Blue – typically 12 gauge)

- Brake Magnets

- Brake Shoes & Drum Assembly

- Ground Circuit (White – critical)

How Power Flows Through the System

| Component | Function |

|---|---|

| Brake Controller | Sends variable voltage based on braking force |

| Blue Wire | Delivers power to trailer brakes |

| Brake Magnet | Electromagnet that engages brake shoes |

| Ground (White Wire) | Completes electrical circuit |

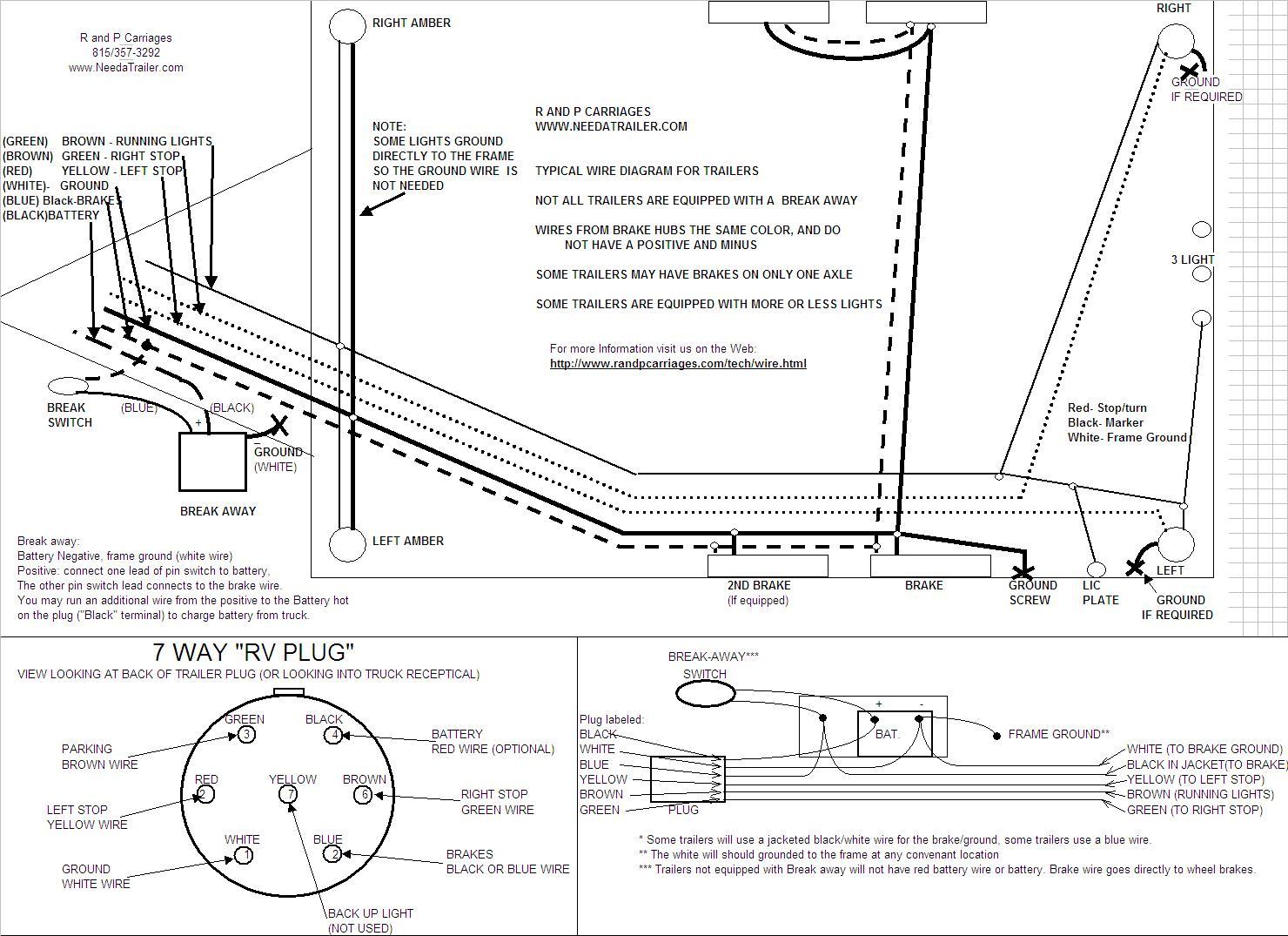

7-Way Wiring Diagram Reference

Electric brakes operate through the 7-way connector. The brake signal is carried on the blue wire from the controller.

Wire Size Requirements for Electric Brakes

| Gauge | Max Load | Typical Use |

|---|---|---|

| 16 Ga | 10 Amps | Lights only (NOT recommended for brakes) |

| 14 Ga | 15 Amps | Up to 2 brake axles (light duty) |

| 12 Ga | 20 Amps | 3 brake axles / Standard brake wiring |

| 10 Ga | 30 Amps | Heavy duty, long runs, campers, high draw |

If you have multiple brake axles, hydraulic pumps, interior lighting, or use the 12V auxiliary circuit, calculate your total load before selecting wire size.

Grounding – The #1 Brake Failure Cause

- Never rely on the hitch ball for ground.

- Ground wire must be securely attached to trailer frame.

- Ground should be attached in multiple locations when possible.

- Ground wire must match brake wire gauge.

Common Electric Brake Problems

- Weak or no braking force

- Uneven braking side to side

- Locking wheels under light pedal

- Brake controller error codes

- Blown fuse in brake controller circuit

- Broken or undersized brake wire

- Corroded 7-way terminals

Brake Magnet Testing

Brake magnets can be tested with a multimeter by checking resistance (ohms). Typical values vary by brake size:

| Brake Size | Typical Magnet Resistance |

|---|---|

| 7" | Approx. 3.0 – 3.8 Ohms |

| 10" / 12" | Approx. 3.0 – 3.5 Ohms |

Always test magnets individually and verify wiring continuity.

Important Note About Brake Lights

Trailers do NOT have separate brake lights. They use:

- Left Turn / Stop

- Right Turn / Stop

If turn signals work but brake lights do not, the issue is typically on the truck side — not the trailer.

Maintenance & Preventative Care

- Inspect wiring annually.

- Check 7-way terminals for corrosion.

- Grease plug terminals to prevent oxidation.

- Inspect brake shoe wear and magnet surface.

- Burnish new brakes after installation.

The green corrosion seen inside plugs is copper oxide. Regular grease prevents moisture intrusion and oxidation.

When to Replace Electric Brakes

- Worn brake shoes

- Grooved drum surface

- Overheated magnets

- Weak braking after adjustment

- Damaged backing plates

Proper wire sizing, secure grounding, and correct controller setup are the foundation of reliable trailer braking. When diagnosing electric brake issues, always verify voltage at the 7-way, confirm magnet resistance, and inspect ground integrity before replacing components.

0 comments